點焊(han)(han)(han)(han)機(ji)點�����焊(han)(han)(han)(han)規范(fan)(fan)是指(zhi)在完成一(yi)次(ci)點焊(han)(han)(han)(han)循環中決定(ding)決定(ding)過程進行的(de)工藝(yi)參(can)數(shu)的(de)綜(zong)合。焊(han)(han)(han)(han)接(jie)(jie)(jie)規范(fan)(fan)是決定(ding)焊(han)(han)(han)(han)接(jie)(jie)(jie)質(zhi)量的(de)重要(yao)因素(su)之(zhi)一(yi)。點焊(han)(han)(han)(han)機(ji)點焊(han)(han)(han)(han)時,焊(han)(han)(han)(han)接(jie)(jie)(jie)電(dian)流大(da),通電(dian)時間短(duan)。通常,習(xi)慣把(ba)一(yi)次(ci)通電(dian)稱作(zuo)一(yi)個電(dian)流脈沖(chong)。每(mei)焊(han)(han)(han)(han)接(jie)(jie)(jie)一(yi)個焊(han)(han)(han)(han)點都需(xu)要(yao)一(yi)個或幾個用來形成熔核的(de)主(zhu)脈沖(chong)。根據(ju)材料點焊(han)(han)(han)(han)的(de)要(yao)求,有(you)時還帶有(you)預(yu)熱和(he)后熱等輔助(zhu)電(dian)流脈沖(chong),以及階梯電(dian)極(ji)壓(ya)力(li)或馬鞍(an)形電(dian)極(ji)壓(ya)力(li)。����因此(ci),就有(you)了單脈沖(chong)規范(fan)(fan)、雙脈沖(chong)規范(fan)(fan)、多脈沖(chong)規范(fan)(fan)和(he)變壓(ya)力(li)規范(fan)(fan)。

點焊(han)(han)機點焊(han)(han)規范(fan)參(can)數主(zhu)要有焊(han)(han)接(jie)(jie)電(dian)(dian)(dian)流(liu)(liu)、焊(han)(han)接(jie)(jie)時(shi)間(jian)、電(dian)(dian)(dian)極(ji)(ji)壓(ya)(ya)力(li)和電(dian)(dian)(dian)極(ji)(ji)端面(mian)(mian)尺寸(cun)(cun)。下(xia)(xia)面(mian)(mian)重(zhong)點介(jie)紹下(xia)(xia)點焊(han)(han)機電(dian)(dian)(dian)極(ji)(ji)壓(ya)(ya)力(li)。電(dian)(dian)(dian)極(ji)(ji)壓(ya)(ya)力(li)過(guo)大過(guo)小都會(hui)使焊(han)(han)點的承載能力(li)降低(di)和分散性(xing)變大,尤其對拉伸(shen)(shen)載荷影響更大。電(dian)(dian)(dian)極(ji)(ji)壓(ya)(ya)力(li)過(guo)小時(shi),由于焊(han)(han)接(jie)(jie)區金屬的塑性(xing)變形(xing)范(fan)圍(wei)及變形(xing)程度(du)不足,造成(cheng)因電(dian)(dian)(dian)流(liu)(liu)密(mi)度(du)過(guo)大而(er)引起加(jia)熱速(su)度(du)增(zeng)大,������塑性(xing)環又來不及伸(shen)(shen)展,從(cong)而(er)產生(sheng)(sheng)嚴重(zhong)噴濺。這(zhe)不僅使熔核形(xing)狀和尺寸(cun)(cun)發生(sheng)(sheng)變化,而(er)且(qie)污(wu)染環境(jing)和不安全,這(zhe)是不允(yun)許的。電(dian)(dian)(dian)極(ji)(ji)壓(ya)(ya)力(li)過(guo)大將接(jie)(jie)觸(chu)面(mian)(mian)積(ji)增(zeng)大,總電(dian)(dian)(dian)阻和電(dian)(dian)(dian)流(liu)(liu)密(mi)度(du)減(jian)小,焊(han)(han)接(jie)(jie)散熱增(zeng)加(jia),因而(er)熔核尺寸(cun)(cun)下(xia)(xia)降,嚴重(zhong)時(shi)會(hui)出現未焊(han)(han)透缺陷。

一般認為(wei)(wei)在增加(jia)電極(ji)(ji)壓力的(de)(de)同時,適當加(jia)大(da)焊(han)(han)接(jie)電流或(huo)是焊(han)(han)接(jie)時間,以維持焊(han)(han)接(jie)區的(de)(de)加(jia)熱程(cheng)度(du)不(bu)(bu)變(bian)。同時由于(yu)壓力增大(da),可(ke)消(xiao)除(chu)焊(han)(han)件(jian)裝配間隙(xi)、剛性(xing)不(bu)(bu)足因素引起(qi)的(de)(de)不(bu)(bu)良影(ying)響(xiang)。因此,不(bu)(bu)僅焊(han)(han)點強度(du)維持不(bu)(bu)變(bian),穩定性(xing)也大(da)������為(wei)(wei)提高(gao)。但(dan)電極(ji)(ji)壓力的(de)(de)增大(da)受焊(han)(han)機功率的(de)(de)限制。

微信公眾號

微信公眾號 無錫(xi)阿里店鋪

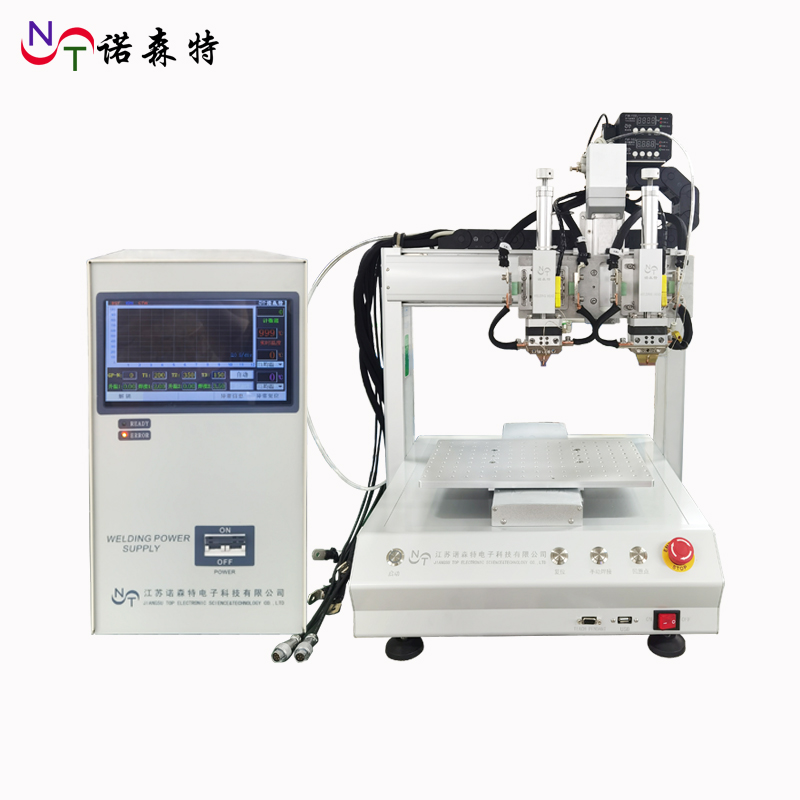

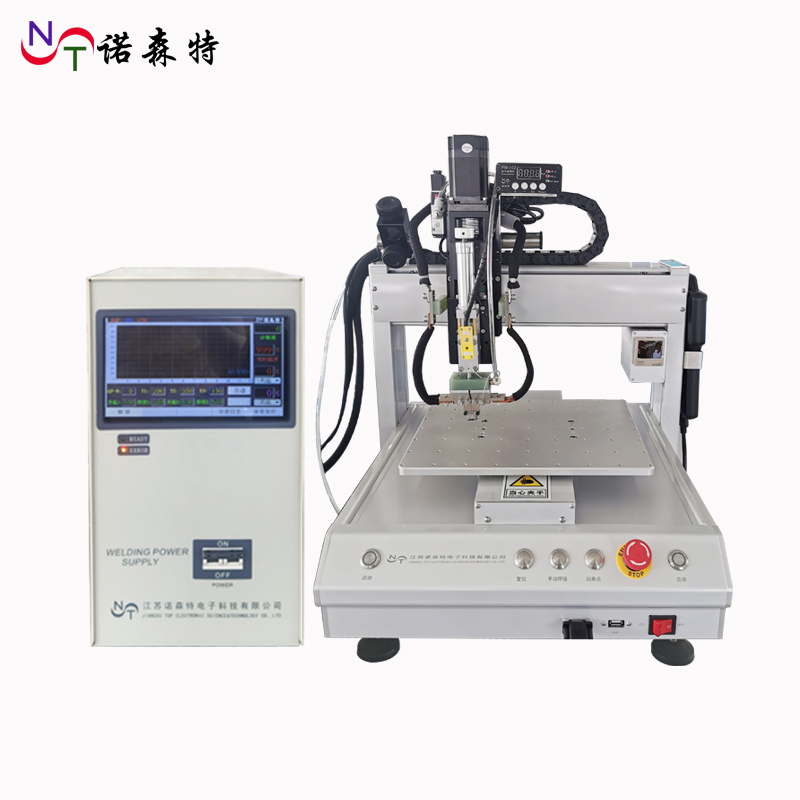

無錫(xi)阿里店鋪 自動焊接(jie)設備生(sheng)產廠家(jia)

自動焊接(jie)設備生(sheng)產廠家(jia) 精密焊接設備(bei)生產廠家

精密焊接設備(bei)生產廠家 電焊機(ji)廠家店

電焊機(ji)廠家店

中文

中文